The development and production of high-frequency antennas is a complex field that requires a wide range of expertise and skills. RF SPIN has almost twenty years of experience in this demanding discipline, thanks to which it now supplies broadband antennas with top parameters and highly functional designs to the whole world.

The path to a successful product always begins with an ingenious and well-thought-out design down to the smallest detail. Of course, advanced software tools help us to achieve perfect results, but the essence of any great antenna concept lies primarily in the clever considerations and experience gained by people in the development and design department of RF SPIN.

Our own production facility guarantees us control over the entire process

In the production of RF SPIN antennas, we place emphasis on every detail that can affect their performance, accuracy, reliability, and durability.

Therefore, 100% control over the entire process is key for us – from the initial computational and mechanical design through the selection of materials to the precise production, surface treatment, assembly, and subsequent measurement and certification of parameters and characteristics of our antennas.

100 percent control over the entire process is the key.

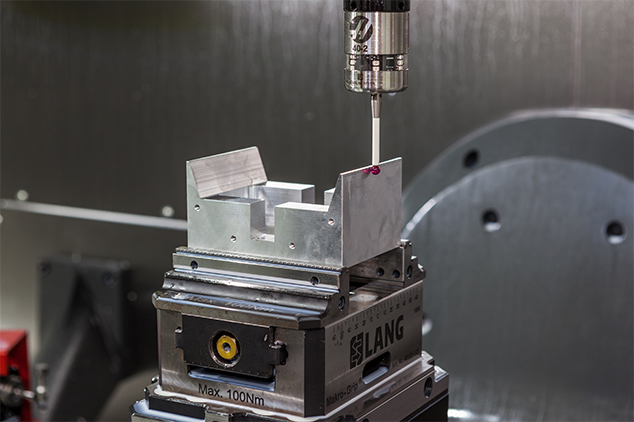

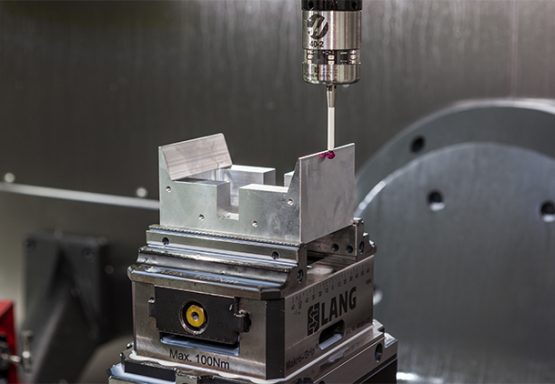

Thanks to the fact that our own production facility in the Czech Republic has a wide range of top machines for high-precision metal machining, we are able to produce unprecedentedly accurate components for the complete portfolio of our antennas.

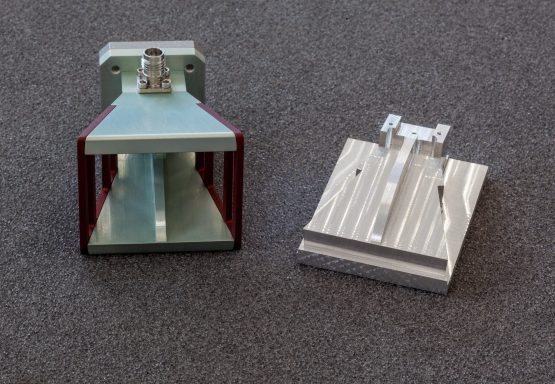

We can design and supply our customers with extremely compact antennas composed of a smaller number of parts. More importantly, the key performance parameters of our antennas are above average in the industry and outperform many competitors in their classes.

Top-quality as a result of precise and careful production controls

In the production division of our company, we have implemented a number of sophisticated control mechanisms, thanks to which we are able to achieve levels of production accuracy to hundredths, and in some cases up to thousandths of millimeters.

The accuracy of production is a fundamental prerequisite for the individual components to fit together perfectly during the final assembly, and the antennas thus have exceptional characteristics, especially in the high-frequency bands.

During the production process, each manufactured component undergoes continuous control measurements and we constantly verify the technical and parametric criteria of all production machines.

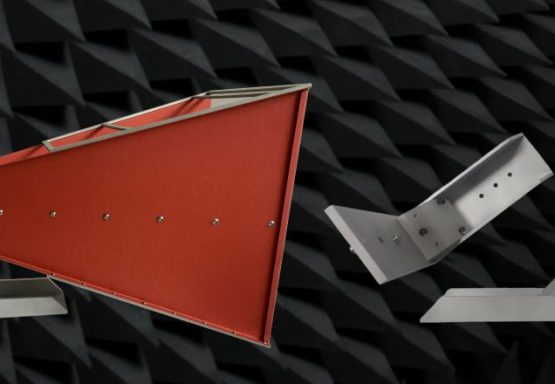

This gives us the ability to produce a higher number of antennas with identical properties and parameters. In the measuring chamber, we also subject all assembled antennas to thorough calibration measurement.