Core materials for production of top quality RF equipment

The key properties of the material suitable for antennas are lightweight, strong, corrosive-resistant , and for certain products also conductive. However, the portfolio of practically usable materials also defines the production technologies, the purpose of the given radio equipment, and also its required properties. This is why RF SPIN relies on advanced aluminum alloys in the production of most antennas which have top properties and at the same time can be machined well.

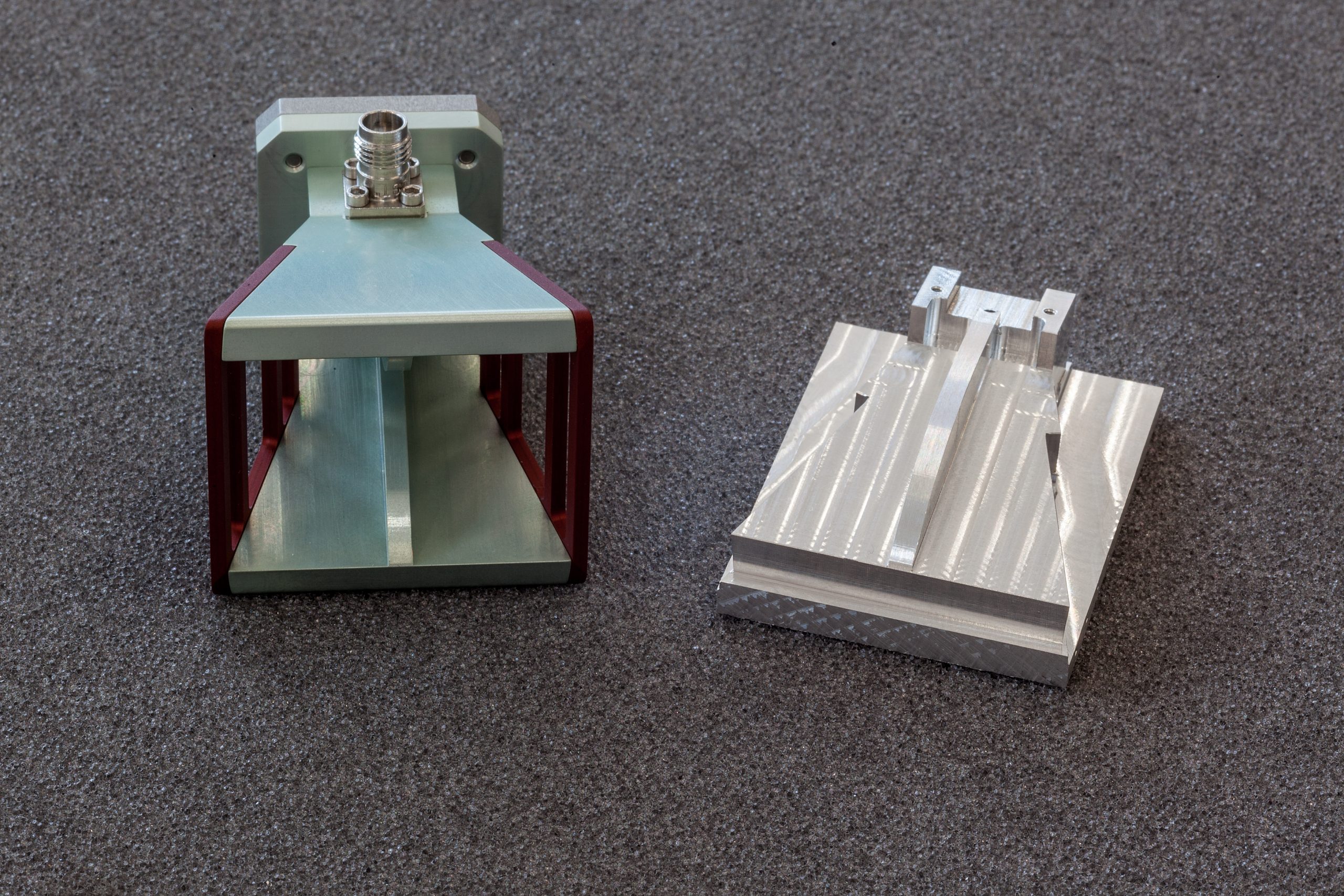

For funnel antennas, the design of which requires a maximum increase in the conductivity of the entire structure, we use brass as it allows us to effectively apply a very conductive layer of gold. However, the surfaces of the materials used always need to be further treated, which gives the antennas even better properties – excellent corrosion resistance, abrasion resistance, thus longer life, and depending on the type of surface also higher conductivity, a luxurious appearance, and the ability to adapt the surface color according to customer requirements.

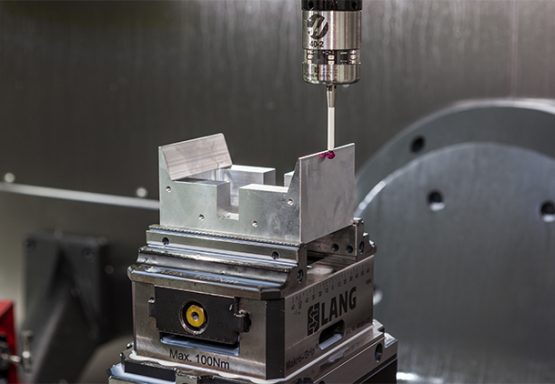

Importance of technology in a fraction of a millimeter

Although the surface treatment reaches a thickness of several hundredths of a millimeter, it has a significant effect on the key performance parameters of the antennas. This is especially evident in the high-frequency bands, and the influence of even such a thin layer must be considered in the design of RF SPIN high-precision antenna components.

Aluminum and brass surfaces can be treated with a number of chemical chemicals , depending on the specific use of the product. For the production of broadband antennas, we use those that best allow us to achieve high quality and top parameters of our antennas.

At the same time, in all phases of antenna production, we place great emphasis on minimizing the impact of the raw materials used on the environment and use only those substances that meet the strictest environmental standards.

Passivation of important antenna components

One of the key surface treatments we use on aluminum parts is passivation. By means of a chemical bath, a colorless layer is formed on the treated surfaces, which protects against corrosion and ensures low electrical resistance, and thus a higher conductivity of the material.

We passivate with chromium-free Bonderite 2040 (formerly Alodine), which is one of the best materials in its class. It is by immersion in the passivation bath that the substance coats even the hard-to-reach places of the antenna structure and creates a layer only a few micrometers thin with unique parameters on all treated parts.

The choice of Bonderite / Alodine 2040 material is not random. This advanced preparation has been specially developed to ensure the passivation of aluminum alloys and has replaced previously used materials containing hexavalent chromium. The new Bonderite / Alodine 2040 does not contain any such hazardous substances, which means that all RF SPIN antennas meet the requirements defined in the RoHS Directive and do not harm the environment.

For hardness, durability, and color

The second type of finishing of aluminum materials used is anodizing, i.e. the formation of an anodic oxide coating on the surface of the part. Since the anodized surface has a very low conductivity, it is used on those parts of the antennas that do not need to be electrically connected to the antenna connector.

Thanks to this compact protective layer which is created by an electrochemical process, aluminum is subsequently very resistant to mechanical damage, has a higher hardness, and is abrasion resistant. This dramatically increases the robustness of the antenna and thus its lifespan and ability to operate in harsh conditions.

An interesting advantage of this treatment is that, with a good choice of anodizing bath, the resulting part can be painted in virtually any color. Although such an adjustment does not affect the physical properties of the antenna and rather affects its aesthetics, we use it to differentiate the individual antenna parts.

The dye closes in the anodized layer and does not tend to peel off, as is the case with other dyes applied directly to the metal. We also use special colored antenna parts in customer production for important customers, so that the antennas we produce perfectly represent their brand and fit into the existing product portfolio.